Most people don't put much thought into the sandpaper they buy.

But if you ended up here, you're not like most people!

While sandpaper may seem simple on the surface (paper with sand on it??) it's actually quite complex with a multitude of variables that impact how it works.

There's more to it than just the grit number.

So let's get into it.

1. What do the different grits mean in sandpaper?

Sandpaper comes in different grit levels, which are indicated by a number. The higher the number, the finer the grit. For example, 60 grit sandpaper will be more coarse than 120 grit sandpaper.

Ever wonder why?

The numbers are derived from the number of abrasive particles that fit in a 1"x1" square. So the larger the particle, the lower the grit number since fewer of those particles can fit in a 1"x1" square.

We can also determine that 60 grit abrasive particles are roughly twice the size of 120 grit particles.

Here is a closeup of various Serious Grit discs to show the difference in particle sizes:

So which grit should you use?

In general, lower grits (40 to 100) are used for rough sanding, while higher grit numbers (120 to 220) are used to prep for finishing. For most woodworking projects, we recommend using a progression of grits from 80 grit for rough sanding and ending at 220 grit for finishing prep. However, for certain projects such as when using epoxy, you may want to use even higher grits for an ultra-smooth finish.

40-80 Grit

This is a very coarse grit, and is good for removing a lot of material quickly. It is often used for sanding rough surfaces, such as unfinished wood or a surface with heavy paint or rust.

100-120 Grit

This is a medium grit, and is good for smoothing out rough surfaces and removing scratches left by the coarse grit. It is often used for sanding wood in preparation for staining or painting.

150-220 Grit

This is a fine grit, and is good for smoothing out surfaces and preparing them for a final finish. It is often used for sanding wood between coats of paint or stain, or for preparing a surface for a clear coat.

320-800 Grit

These are very fine grits, and are good for achieving a smooth, polished finish. They are often used for sanding between coats of paint or clear coat, or for finishing a surface to a high shine.

Sanding Grit Progression

It is also important to know about progressing through the grits when sanding.

Each grit level removes the scratches left by the previous grit, and prepares the surface for a smoother finish. So starting with a coarse grit and progressing to a finer grit gradually smooths out the surface, balancing efficiency with finish quality.

For example, if you start with a very fine grit sandpaper, you may not be able to remove all the deep scratches or imperfections on the surface. In this case, you would need to start with a coarser grit sandpaper and gradually work your way up to a finer grit to achieve the desired smoothness.

In addition, skipping grit levels can cause problems with the final finish. For example, if you skip from a coarse grit to a very fine grit, the fine grit may not be able to remove all the scratches left by the coarse grit, resulting in a rough finish with deep grooves left form the coarse grit. Similarly, if you start with a very fine grit and skip to a coarse grit, the coarse grit may leave deep scratches that are difficult to remove with the finer grits.

By properly progressing through the grits, you can achieve a smooth, even finish that is free of scratches and imperfections. This is especially important when working on wood, where a smooth surface is essential for achieving a professional-looking finish. For reference, our assorted grit boxes contain 10 discs each of 80, 120, 150, 180, and 220 grit. This takes the guesswork out of the grit progression and gives you everything you need for a smooth finish on your next project.

2. What do the different backings mean in sandpaper? Paper vs film vs mesh sanding discs.

You may have noticed that sandpaper comes in a variety of backing materials including paper, cloth, film, and mesh/nets. Not to be confused with the attachment method for sanding discs (hook and loop or PSA), the sandpaper backing refers to the material that the abrasive grain is bonded to and it is sandwiched between the grain and the hook and loop material.

When it comes to sanding discs, most are either paper, film, or mesh/net-backed.

So which is better and how do you choose?

Paper-backed sanding discs

Paper-backed discs are made by adhering a layer of abrasive grit to a paper backing (typically C-weight). They are the most common type of sanding disc and generally what you'll find at the big box stores as they are the cheapest to produce. The downside is that they are more fragile so you'll often see them tearing around the edges or cracking when you fold them for hand-sanding pieces. This means you'll be replacing them more often and the upfront cost savings may be negated rather quickly.

Film-backed sanding discs

Film-backed sanding discs, as the name suggests, are made by adhering the abrasive grit to a thin polyester film backing. While this method is more expensive to produce vs paper-backed discs, they are far more durable and long-lasting. This makes them the better choice for those who are serious about their sanding!

Besides durability, film-backed discs also have a few additional advantages. First, because the film is stronger than the paper backing, the discs end up being flatter and more uniform, leading to a better finish quality. They can also be used in wet-dry sanding applications because the film is waterproof.

These benefits are a big reason why we chose film for the backing material on Serious Grit sanding discs. While the price may be higher than paper, the durability more than makes up for the difference.

Net/Mesh-backed sanding discs

Initially introduced by Mirka with their Abranet line of sanding discs, mesh or net discs have gained popularity the past several years. These discs have grain adhered to a mesh backing similar to what you'd see on a window screen. Instead of having holes cut out for dust collection, these discs have tiny holes placed throughout the entire disc.

Here's a closeup shot showing how this works:

While this is advantageous for dust collection, mesh discs haven't gained widespread adoption due to a couple distinct disadvantages.

First of all, the mesh backing lacks the surface area of a film or paper disc for hook and loop material so these discs often have issues sticking to sanders. Here is a closeup showing the hook and loop backing of a 3M Xtract mesh disc:

Some companies offer interface pads to help with this, but they're still prone to flying off your sander while using them.

Secondly, mesh discs often tear along the edges prematurely which leads to them needing replacing more often than film discs or even paper discs. While the abrasive grain may still have life left, the backing is no longer intact and the disc needs to be replaced.

3. Hook & Loop vs PSA (Pressure Sensitive Adhesive) Sanding Discs

When shopping for sanding discs you may have have seen some advertised as Hook & Loop and others as PSA. This refers to how the sanding discs attach to your sander.

Hook & Loop Discs

Hook and loop discs are also known informally as Velcro discs, but Velcro is actually a brand name. Similar to Kleenex, Xerox, etc.

They have a nylon fabric backing with small loops that attach to the corresponding hooks on your sander's backing pad.

Here's an extreme closeup to show what we're talking about (Note the writing marks and the hole in the disc at the bottom of the image to get a sense of the scale here).

Hook and loop discs are easy to attach and remove, which make them convenient for switching between grits or when you need to replace a worn disc. They are the most common type of discs used for woodworking. Nearly all sanders marketed toward woodworkers will have hook and loop backing pads.

PSA (Pressure Sensitive Adhesive) Discs

On the other hand, PSA discs have a sticky adhesive backing that sticks directly to your sander's pad. PSA discs are generally found on pneumatic sanders used by auto body and paint shops. They often have no holes because dust collection is usually not built into these types of sanders so there is no need for holes.

Overall, the choice between hook and loop and PSA discs really comes down to the type of sander you're using and what you'll be sanding.

4. What are the different abrasive grains used in sandpaper?

There are a variety of abrasive grains used in sandpaper: Aluminum Oxide, Zirconia Alumina, Ceramic Alumina, Silicon Carbide, and Garnet.

Each have their own special place in the world of sanding. Here is a breakdown:

Aluminum Oxide

This is the most common abrasive used in sanding discs. It's tough, durable and ideal for sanding hardwoods, softwoods, painted surfaces, and much more. Part of what makes aluminum oxide a good choice for woodworkers is its balance of price and durability. Durability in sandpaper grain is based on the hardness and friability of the grain. In simple terms, friability refers to the ability of the abrasive particles to break down during use. A more friable abrasive means that the individual abrasive particles will break down more easily, revealing new sharp edges that can continue to abrade the surface being sanded. You'll often see this referred to as self-sharpening sandpaper. As you sand, the grain breaks down and exposes new sharp edges in order to maintain its cutting power.

Zirconia Alumina

This abrasive is a combination of aluminum oxide and zirconium oxide, making it exceptionally durable and tough. It's ideal for sanding metals, especially stainless steel, and is also effective at removing paint and rust. At Serious Grit, we use Zirconia Alumina in our 40, 60, 80, 100, and 120 grit discs in order to make them more durable. The only downside of zirconia alumina is that it's more expensive than other abrasives.

Ceramic Alumina

Ceramic Alumina (often referred to as simply Ceramic) is the most durable and long-lasting of all the abrasives. It's ideal for heavy-duty sanding applications, such as sanding metal, hard plastics, hardwoods, and composites. It's also excellent at removing surface defects and scratches. The primary downside of ceramic alumina is that it's the most expensive abrasive.

Silicon Carbide

This abrasive is harder and sharper than aluminum oxide, making it ideal for sanding non-ferrous metals, fiberglass, and plastics. It's also effective at removing rust and paint from metal surfaces. However, it's not as durable as aluminum oxide and can wear down quickly when used on hardwoods. For this reason, silicon carbide is typically not used in most woodworking applications.

Garnet

Garnet abrasive grain is a natural mineral that has been used in sandpaper for over a century. It has a reddish-brown color and is often used in woodworking applications because it is softer than other abrasive grains, which means it is less likely to scratch or damage the surface being sanded.

However, there are some drawbacks to using garnet sandpaper. Because it is a softer abrasive, it may not be as effective at removing heavy layers of material or sanding harder surfaces like metal or plastic. It also has a shorter lifespan than some other abrasive grains, which means it may need to be replaced more frequently.

Overall, the choice of abrasive grain will depend on the specific material being sanded and the desired level of aggressiveness. For most woodworking projects, aluminum oxide is a good all-around choice, while zirconia alumina and ceramic alumina are ideal for heavy-duty sanding applications. Silicon carbide is best suited for non-ferrous metals, fiberglass, and plastics.

5. What is Stearate in sandpaper?

You may see some sanding discs advertised with stearate included. This refers to a coating that is applied to the abrasive grain in order to improve performance and prolong the life of the sandpaper.

Stearate is a generic term that refers to a type of chemical compound that is often used as a coating on sandpaper. It is typically made from a fatty acid and a metal salt, and it can provide a number of benefits. For example, stearate can help to prevent the abrasive grains from clogging with dust, which can help to improve the sanding efficiency and prolong the life of the sandpaper. It can also reduce friction between the abrasive grains and the workpiece, which can help to prevent heat buildup and reduce the risk of burning the surface being sanded.

Zinc stearate (used in Serious Grit sanding discs) is a specific type of stearate that is made by combining stearic acid with zinc oxide. It is often used as a coating on sandpaper because it provides some additional benefits compared to other types of stearate. For example, zinc stearate can help to reduce the heat buildup during sanding, which can help to prevent the sandpaper from clogging and prolong its life. It can also provide some lubrication between the abrasive grains and the workpiece, which can help to reduce the risk of scratching or gouging the surface being sanded.

6. Open vs Closed Coat Sandpaper

What is the difference between open coat and closed coat sandpaper?

Sandpaper can be classified as open coat or closed coat based on the spacing between the abrasive particles.

Open coat sandpaper has more space between the abrasive particles and is best suited for sanding softer materials such as wood.

Closed coat sandpaper has less space between the abrasive particles and is best suited for sanding harder materials such as metal.

Serious Grit sandpaper is open coat and most other sandpapers you'll find for woodworking are also open coat.

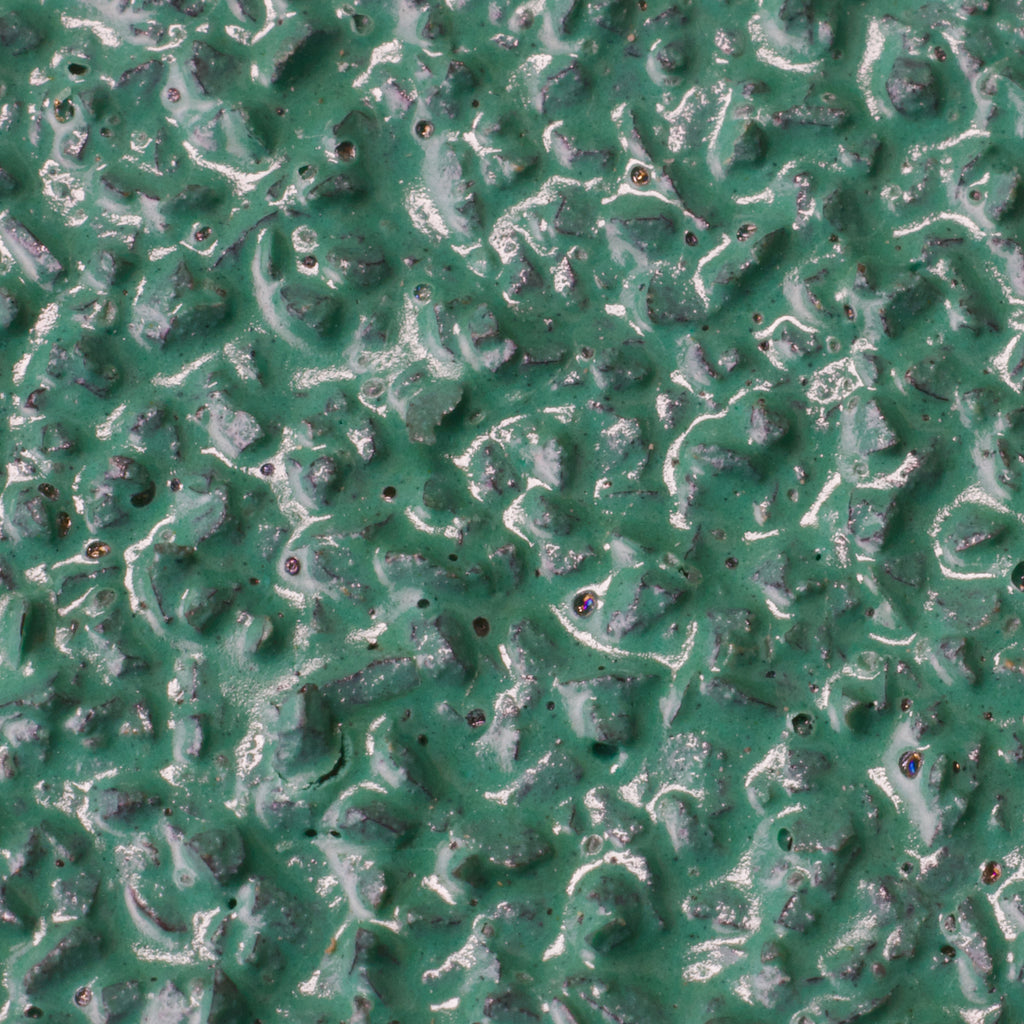

Here is a closeup showing Serious Grit's open coat grain on a 40 grit disc:

So there you have it!

You now know more than you ever wanted to know about sandpaper. Now take this newfound knowledge out into the world and choose your abrasives wisely. 😎

Hi

My next purchase of sandpaper will be yours.

Thanks Terry

Comments